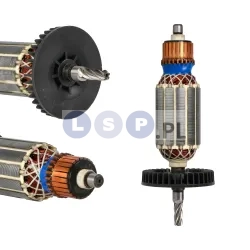

Rotors

Rotors are key components in a variety of power tools, ensuring that they work by generating the rotational motion necessary to perform work such as drilling, cutting or grinding. Our product range includes rotors for: grinders, drills, hammer drills, demolition hammers and other equipment. Reputable brands such as BOSCH, MAKITA, HITACHI, HIKOKI, METABO, DeWALT, HILTI, as well as market, Chinese brands.

How to choose the right rotor?

Each rotor has an original part number for easy selection for branded power tools. For market, Chinese tools, each rotor has dimensions that should be compared with the old part.

-

Wiatrak wentylator do wirnika GSH 27

Średnica Zewnętrzna: 99mm

Średnica Wewnętrzna: 12/15mm (za tuleją)

Grubość: 20mm

Indeks: 14-008 -

Wirnik typ BOSCH wiertarka CSB PSB GSB 18-2 20-2

Wirnik przeznaczony do wiertarki Bosch GSB 18-2 RE. Wirnik pasuje również do: GSB 2-600 RE, GSB 2-650 RE,CSB 650-2 RE, CSB 650-2 RET, CSB 650-2 RP, CSB 6-20 zamiennik: 2 604 010 862, 2 604 011 090 RE, GSB 20-2 RE, GSB 18 RE, GSR 6-20 TE, GSR 8-6 KE, GSB 8-16 KE, CSB 700-2 RE, CSB 680-2 RE.

Indeks: 21-001 -

Wirnik wiertarki BOSCH GSB 16 RE 2604011077

Wirnik do wiertarki Bosch GSB 16 RE.

Numer katalogowy oryginalny: 2604011077

Wirnik pasuje do elektronarzędzi o numerach:

0 601 140 603

0 601 140 608

0 601 140 637

0 601 140 642

0 601 140 650

0 601 140 670

0 601 140 676Indeks: 21-003 -

Wirnik wiertarki BOSCH PSB 450, 2604011173

Wirnik do wiertarki Bosch PSB 450. Wirnik pasuje również do: PSB 450-2, PSB 450 RE, PSB 500 RE, PSB 13 RE,PSB 530 RE, PSB 600 RE, PSB 13 RE, PSB 550 RE, PSB 2000.

Numer katalogowy oryginału: 2604011173

Indeks: 21-004 -

Wirnik do wiertarki Bosch PSB 600 RE 650 2604011154

Wirnik do wiertarki PSB 600 RE. Wirnik pasuje również: PSB 600-2, PSB 570 RE, PSB 15 RE, PSB 5-15 RE, PSB 6E, PSB 600 RE, PSB 580 RE, PSB 16 RE, PSB 6-16 RE, SB 600 RPE, PSB 650-2, PSB 650 RE, PSB 650 RPE.

Numer katalogowy oryginału: 2604011154

Indeks: 21-006 -

Wirnik do wiertarki Bosch GSB13, GSB13RE, 2604011259

Wirnik do wiertarki Bosch GSB13, GSB13RE.

Numer katalogowy oryginalnej części: 2604011259

Indeks: 21-007 -

Wirnik do wiertarki Bosch GSB 20-2 RCE 4 zęby

Wirnik do wiertarki Bosch GSB 20-2 RCE.

Przed zakupem proszę porównać wirnik. Proszę zwrócić szczególną uwagę na kierunek i ilość zębów.

Zdjęcie przedstawia rzeczywisty produkt.

ZDJĘCIE Z WYMIARAMI MA CHARAKTER POGLĄDOWY.

Indeks: 21-008 -

Wirnik do wiertarki Bosch GSB16, GSB16RE, 2604011254

Wirnik do wiertarki Bosch GSB16, GSB16RE.

Numer katalogowy oryginalnej części: 2604011254

- 0601148003

- 0601148603

- 0601148608

- 0601148663

- 0601148703

- 0601148708

- 0601148763Indeks: 21-009 -

Wirnik Bosch GWS 6-125, 115E, 115, 1604010626

Wirnik do szlifierki kątowej GWS 6-115, -115E, -125. Wirnik pasuje również do GWS 6-115, GWS 6-125, GWS 660, GWS 6-115 E, GAF 22 A.

Numer katalogowy oryginału: 1604010626

Indeks: 21-010 -

Wirnik szlifierki BOSCH GWS850C GWS850CE 8-125

Wirnik do szlifierki kątowej Bosch GWS 850 C.

Numer katalogowy oryginału: 1 604 010 667

Pasuje również do: GWS 850C, GWS 850CE, GWS 780C, GWS 8-100C, GWS 8-125C, GWS 780C, GWS 8-100CE, GWS 8-125CE

Indeks: 21-012 -

Wirnik BOSCH GWS 10-125 C CE PWS 10 HILTI AG

Wirnik do szlifierki kątowej Bosch GWS 10 C. Pasuje również do: GEB 1000 CE, OSB 1020 CE, nowy typ: GWS 10-125 CE, PWS 10-125 CE, HILTI AG 125 S

Numer katalogowy oryginału: 1 604 010 640

Indeks: 21-015 -

Wirnik szlifierki BOSCH GWS 1000 GWS 10-125

Wirnik do szlifierki kątowej GWS 1000.

Numer katalogowy oryginału: 1 604 010 A20

Zastosowanie:

GWS 10-125 Z

GWS 9-125 (0601801008)

GWS 1000

GWS 10-125 /BEZ OZNACZENIA C LUB CE /Indeks: 21-016 -

Wirnik typ BOSCH GWS 11-125 CI CIE HILTI DAG DC

Wirnik do szlifierki kątowej GWS 11-125 CI. Wirnik pasuje również do: GWS 11-125 CI, GWS 11-125 CIE, GWS 11-125 CIH. HILTI DAG125SE DAG 125S

Numer katalogowy oryginału: 1604010A21

Indeks: 21-017 -

Wirnik szlifierki typ BOSCH GWS 14 -125 PWS 13

Wirnik do szlifierki kątowej GWS 14-125 NT.

Numer katalogowy oryginału: 1 604 010 650

Pasuje do:

GBR14CA (601773703)

GWS14-125C (601804503)

GWS14-125C (601704703)

GWS14-125CE (601805708)

GWS14-125CE (601805508)

GWS14-125CE (601705708)

PWS 13-125 CE - pasuje tylko do starego typu bez regulacji obrotów!

Indeks: 21-018 -

Wirnik BOSCH GWS 14-125 CI CIE 1400 1604010A90

Wirnik do szlifierki kątowej Bosch GWS 14-125 CIE CE.

Szlifierka kątowa: GWS1400, GWS1400C, GWS14-125CI, GWS14-125CIE, GWS 1400, GWS 1400C, GWS 14-125CI, GWS 14-125CIE,

Nr kat.: 1604010A90, 1604010A22, 1604010A86

Indeks: 21-020 -

Wirnik szlifierki Bosch GWS PWS 20-180 20-230 21-180

Wirnik do szlifierki kątowej GWS 20-230 oraz do PWS 18, 19.

Numer katalogowy oryginału: 1604011145/1604011148

Wirniki pasuje również: GWS 19-180, GWS 2000-180J, GWS 19-230,GWS 2000-230, GWS 2000-230 J, GWS 21 U, GWS 21-180, GWS 20-230, GWS 21-230, PWS 1700, PWS 20-230, PWS 18-230 J.

Indeks: 21-021 -

Wirnik szlifierki Bosch GWS 20-230 GWS 21-180 GWS 21-230

Wirniki pasuje: GWS18U, GWS21U, GWS18-180, GWS19-180, GWS19-230, GWS20-180, GWS20-230, GWS21-180, GWS21-230, GWS2000-230, PWS18-230, PWS19-230, PWS20-230J, PWS 18-230J, GWS 18-180, GWS 19-180, GWS19-230, GWS 20-180, GWS 20-230, GWS 21-180, GWS 21-230, GWS 2000-230, PWS 18-230, PWS 19-230, PWS 20-230J, PWS 18-230J

Numer katalogowy oryginału: 1604011148

Indeks: 21-022 -

Wirnik szlifierki BOSCH GWS 23-230 GWS 24-230

Wirnik do szlifierki kątowej GWS 23-230. Wirnik pasuje również do: GWS 23-180, GWS 23-230, GWS 24-180, GWS 24-230, GWS 24-300J, GNF 65 A.

Numer katalogowy oryginału: 1604011153

Indeks: 21-023 -

Wirnik szlifierki BOSCH PWS 550 600 700 6 7 115 125

Wirnik pasujący do szlifierek kątowych Bosch PWS 550 . PWS 600 . PWS 650 . PWS 700

Numer katalogowy oryginału: 2609000761

Indeks: 21-024 -

Wirnik szlifierka Bosch PWS 8-125 9-125 CE

Wirnik do szlifierki kątowej Bosch PWS 9-125 CE.

Numer katalogowy oryginału: 2609000763

Zastosowanie:

GWS 9-125 CS

GWS 9-125 CM

GWS 9-125 CE

GWS 9-150 C

GWS 9-125 C

WS 125 S

GNF 20 CA

R-115

PWS 8-125 CE

PWS 850 CE

PWS EDITION

PWS 9-125 CE

PWS 9-125 X-CEL

PWS 8-125 CE

ORAZ NARZĘDZI SKIL

9280

9285

9290 A1

9290 J1

9295 A1

9295 C1Indeks: 21-025 -

Wirnik Bosch GGS 27 C POF 600 ACE GKF 600 CE GGS27

Wirnik do szlifierki prostej Bosch GGS 27 C POF 600 ACE GKF 600 CE

Numer katalogowy oryginału: 2 604 010 769

Indeks: 21-026 -

Wirnik typ BOSCH PBH 160 R PBH 200 180 RE

Wirnik do młotowiertarki Bosch PBH 160 R, PBH 160, PBH 200 RE, FRE, PBH 180 RE.

Numer katalogowy oryginalnej części: 1614010144

Indeks: 21-027 -

Wirnik Bosch GBH 2-22 GBH 2-23 GBH 2200 1617000524

Wirnik do młotowiertarkek Bosch:

GBH 2-22 S , GBH 2-23 RE , GBH 2-22 ,GBH 2-22 RE ,

GBH 2-22 E ,GBH 2-23 S , GBH 2200

Nr. katalogowy: 1617000524

Indeks: 21-029 -

Wirnik Bosch GBH 2-24DSR 2-24 DFR 5 zębów

Wirnik do młotowiertarki Bosch GBH 2-24 5 zębów.

Indeks: 21-030 -

Wirnik GBH2-24DSR GBH2SR GBH2-24DFR 6 ZĘBÓW

Wirnik do młotowiertarki GBH2-24DSR GBH2SR GBH2-24DFR 6 ZĘBÓW

Numer katalogowy oryginału: 1614010227

Indeks: 21-031 -

Wirnik typ BOSCH GBH2-26 2400 2600 GBH 2-26 DRE

Wirnik do młotowiertarki Bosch GBH 2-26 DRE.

Numer katalogowy oryginału: 1614010709 / 1617000560

GBH 2-26 DRE 0 611 253 703 / 708

GBH 2400 3 611 253 803

GBH 2-26 DE 0 611 253 603

GBH 2-26 DFR 0 611 254 703 / 708

GBH 2600 0 611 254 803

GBH 2-26 DBR 0 611 255 503

Indeks: 21-032 -

Wirnik młot BOSCH GBH 5-38 D GSH 388 GBH5400

Wirnik do młota udarowo-obrotowego GSH 388,GBH 5-38, GBH38. GBH 5400 5-38 500 GSH 500

Numer katalogowy oryginału: 1614011083

Indeks: 21-033 -

Wirnik młot BOSCH GBH 4 DSC GBH 4 DFE

Młot Udarowo-Obrotowy GBH 4 DSC, GBH 4 DFE, Numer oryginalny wirnika 1614010128.

WIRNIK DO MASZYNY BEZ ELEKTRONIKI. W PRZYPADKU MŁOTA Z ELEKTRONIKĄ KONIECZNE JEST ODWROTNE PODŁACZENIE DO STOJANA.

PBH 300 E

GBH 4 DSC

DD 540

BBH 4-30 CCE

BHE 4-30 CE

BMH 30-E

GBH 4 DFE

DD 543

GBH 4-TOP

Indeks: 21-034 -

Wirnik typ BOSCH GBH 5-40DE GBH 5-40DCE GSH 5E 5C

Wirnik do młota udarowo-obrotowego GBH 5/40DE, GSH 5E. Wirnik przeznaczony jest również do: Młot udarowo-obrotowy: GBH5-40DE, GBH5-40DCE, GSH5E, GSH5CE, GBH 5-40DE, GBH 5-40DCE, GSH 5E, GSH 5CE

Numer katalogowy oryginału: 1614011098

Indeks: 21-035 -

Wirnik młot Bosch GBH 5/40 DCE, GBH 5CE 1614010180

Wirnik do młota udarowo-obrotowego GBH 5/40 DCE, GBH 5CE.

Numer katalogowy oryginału: 1614010180

Indeks: 21-036 -

Wirnik BOSCH GBH 7DE, 7-45DE, 7-46DE, 1614010213

Wirnik do młota udarowo-obrotowego

Młot udarowo-obrotowy: GBH7DE, GBH7-45DE, GBH7-46DE, GBH 7DE, GBH 7-45DE, GBH 7-46DE

Numer katalogowy oryginału: 1614010204, 1614010205, 1614010213

Indeks: 21-037 -

Wirnik do młota udarowo-obrotowego Bosch GBH 10 DC

Wirnik do młota udarowo-obrotowego Bosch GBH 10 DC.

Numer katalogowy oryginału: 1 617 220 073

Indeks: 21-038 -

Wirnik młot BOSCH GBH 11 DE GSH 11 E

Wirnik do młota kruszącego Bosch GSH 11 E, DE.

Numer katalogowy oryginału: 1 614 011 072

Indeks: 21-039 -

Wirnik młot BOSCH GSH 27, 1614011091

Wirnik do młota wyburzeniowego Bosch GSH 27.

Numer katalogowy oryginału: 1 614 011 091

Indeks: 21-040 -

Wirnik pilarki typ BOSCH PKS 54 CE 1604010451

Wirnik do pilarki Bosch PKS 54, PKS 54 CE.

Numer katalogowy oryginału: 1 604 010 451, 1 604 010 314

Indeks: 21-041 -

Wirnik typ GWS 7-115, GWS 7-125, długi 1619P05210

Wirnik do szlifierki kątowej GWS 7-125

Odpowiednik oryginału 1619P05210

Indeks: 21-043 -

Wirnik typ BOSCH GBH2-28 GBH2-28 D DV DFV

Wirnik do młota udarowo-obrotowego Bosch GBH 2-28 DFV

Nr. katagolowy: 1614010262

GBH 2-28 DV , GBH 2-28 DFV,

GBH 2-28 F , GBH 2-28 , GBH 2-28 D

BHD-2-28 EC

BH 2-28 MES

H 28 MLE POWER

H 28 MLS POWER

Indeks: 21-046 -

Wirnik typ GWS 12-125 CI CIE 13-125 1607000V33

Wirnik do szlifierki kątowej GWS 12-125, GWS 13-125 CI

Odpowiednik oryginału 1607000V33

Zastosowanie:

GWS 12-125 3 601 G93 000

GWS 12-125 CIE 3 601 G94 000

GWS 12-125 CIEP 3 601 G94 200

Indeks: 21-048 -

Wirnik BOSCH GWS15-125 CI CIE GWS17 1607000V35

Wirnik do szlifierki kątowej GWS 15-125

Odpowiednik oryginału 1607000V35

PASUJE DO MODELI : GWS 15-125 CI , GWS 15-125 CIE ,GWS 15-125 CIP , GWS 15-125 CIPX , GWS 15-125 CIEX , GWS 15-125 CIEP , GWS 17-125 CIE , GWS 17-125 CI , GWS 17-125 CIX , GWS 17- 125 CIEX ,

Indeks: 21-049 -

Wirnik typ Bosch wiertarka PSB 400 z prosty ząb

Wirnik do Wiertarki PSB 400 z prostym zębem

Indeks: 21-050 -

Wirnik typ BOSCH GBH 2-18 PBH 2000 2100, 1619P01771

Wirnik do młotowiertarki Bosch PBH 2000 SRE

Numer katalogowy oryginalnej części: 1619P01771

GBH 2-18 RE 3 611 B58 300 / 301

GBH 2-18 RE 3 611 B58 321

PBH 2000 RE 3 603 C44 300

PBH 2000 RE 3 603 CA9 322

PBH 2000 SRE 3 603 C44 301 / 321

PBH 2100 SRE 3 603 CA9 301 / 321

PBH Universal 3 603 CA9 302

PBH 2100 RE 3 603 CA9 320

Indeks: 21-051 -

Wirnik szlifierka BOSCH GWS 15 17-125 CIT 1607000V36

Wirnik do szlifierki kątowej GWS 17-125 CIT

Odpowiednik oryginału 1607000V36

Indeks: 21-052 -

Wirnik BOSCH PBH2500 PBH2600 PBH2500RE PBH2500SRE

Odpowiednik oryginału o numerze: 1619P08993

Indeks: 21-053 -

Wirnik typ BOSCH GSB 16 RE 2604011913

Wirnik do wiertarki GSB 16 RE o numerze 2604011913

Indeks: 21-055 -

Wirnik do wiertarki GSB 1600 . GSB 1600 RE, 2609120235

Wirnik do wiertarki GSB 1600 RE odpowiednik oryginału o numerze katalogowym 2 609 120 235

Indeks: 21-056 -

Wirnik do pilarki Bosch GKS 190, 1619P06345

Wirnik do pilarki GKS 190. Odpowiednik oryginału o numerze 1619P06345.

Indeks: 21-062 -

Wirnik typ BOSCH GWS 9-115 GWS 9-125 GWS 880

Wirnik do szlifierek BOSCH GWS 9 oraz 880.

Pasuje do modeli:

GWS 9-115 (3601C96003)

GWS 9-125 (3601C96004, 3601C960022)

GWS 880 (3601C96005, 3601C96006)

GWS 9-115 S (3601C96101, 3601C96103)

GWS 9-125 S (3601C96102, 3601C96104)

GWS 9-125 P (3601C965P1)

Odpowiednik oryginału o numerze: 1619P10952

Indeks: 21-063 -

Wirnik BOSCH GWS 19-125 CI CIE HILTI AG125-19SE 1600A00D2N

Wirnik szlifierki kątowej Bosch GWX 19-125 S , GWS 19-125 CI , GWS 19-125 CIE

Odpowiednik oryginału o numerze 1600A00D2N.

GWX 19-125 S 3 601 GC8 000

GWS 19-125 CI 3 601 G9N 000

GWS 19-125 CIE 3 601 G9P 000

Indeks: 21-064 -

Wirnik BOSCH GBH 4-32 DFR, BHD SPIT 1614010252

Wirnik do młotowieratrki GBH 4-32 DFR. Odpowiednik oryginału o numerze 1614010252

numer części:

1614010252

Zastosowanie:

BOSCH

GBH 4-32 DFR

BHD-4-1

BTI-BH 4-32 ME

DD544

SPIT 343

BMH 32-XE

Indeks: 21-066 -

Wirnik młot Bosch GBH 8-45D DV, GSH 7 VC 1614010267

Wirnik do młota GSH 7 VC, GBH 8-45. Odpowiednik oryginału o numerze 1614010267

Zastosowanie:

Młot Bosch: GBH8-45DV, GBH8-45D, GSH7VC, GSH9VC,

Indeks: 21-067 -

Wirnik TYP BOSCH GSH 11 VC 1614011120

Wirnik do młota udarowego BOSCH GSH 11 VC (3611C36000)

Odpowiednik oryginału o numerze: 1614011120

Indeks: 21-068 -

Wirnik do młota GSH 27 VC,1614011139

Wirnik do młota GSH 27 VC

numer części: 1614011139

Zastosowanie:

BOSCH

- GSH 27 VC - 3 611 C0A 0H0

- GSH 27 VC - 3 611 C0A 0E0

- GSH 27 VC - 3 611 C0A 090

- GSH 27 VC - 3 611 C0A 0B0

- GSH 27 VC - 3 611 C0A 070

- GSH 27 VC - 3 611 C0A 030

- GSH 27 VC - 3 611 C0A 040

- GSH 27 VC - 3 611 C0A 0K0

- GSH 27 VC - 3 611 C0A 080

- GSH 27 VC - 3 611 C0A 0P0

Indeks: 21-069 -

Wirnik do szlifierki prostej GGS 28 C CE, GGS 28 LC LCE

Wirnik do szlifierki prostej GGS 28. Odpowiednik oryginału o numerze 3 607 030 476.

GGS 28 C 3 601 B20 000

GGS 28 CE 3 601 B20 100

GGS 28 LC 3 601 B21 000

GGS 28 LCE 3 601 B21 100

Indeks: 21-070 -

Wirnik TYP BOSCH GBH 2-24 DRE DFR 2400 7 zębów

Wirnik do nowej generacji młotków udarowych Bosch GBH 2-24.

Odpowiednik oryginału o numerze: 1619P13450

Pasuje do modeli:

GBH 2-24 DRE / GBH240: 3 611 B72 100, 3 611 B72 180, 3 611 B72 1K0, 3 611 B72 1L1

GBH 2-24 DFR: 3 611 B73 000, 3 611 B73 080, 3 611 B73 0K0, 3 611 B73 0L1

WIRNIK POSIADA 7 ZEBÓW I NIE PASUJE DO MŁOTOWIERTAREK W KTÓRYCH WYSTĘPOWAŁY TWORNIKI Z 6 ZĘBAMI.

Indeks: 21-072 -

Wirnik szlifierki TYP Makita GA5030, 4530 517649-4

Wirnik stosowany w szlifierkach:

GA5030, GA4530R, GA5030R, GA4530, PJ7000

Indeks produktu : 22-004

Numer katalogowy oryginału: 517649-4

Indeks: 22-004 -

Wirnik do MAKITA 9565 CVR 9565CV 9565CR 9565C 515228-2

Wirnik do szlifierki kątowej MAKITA.

Wirnik montowany w:

- 9565CV 9565CVR (niektóre typy) 9565CR 9565C

Odpowiednik oryginału o numerze:

- Wirnik: 515228-2

Zdjęcie przedstawia rzeczywisty produkt.

Indeks: 22-005 -

Wirnik szlifierki MAKITA GA9020 GA9020R GA9020S

Wirnik do szlifierki kątowej Makita GA 9020, MT 900, MT 901, GA7020, GA7020R. GA7020SF

Numer katalogowy oryginału: 517793-7

Indeks: 22-006 -

Wirnik MAKITA GA 9030 GA 7030R GA 9030R GA 7030S

Wirnik do szlifierki kątowej Makita GA 9030, GA7030R, GA9030R, GA7030s, GA9030 S.

Numer katalogowy oryginału: 517928-4

Indeks: 22-007 -

Wirnik szlifierki MAKITA GA9040 GA9040R

Wirnik do szlifierki kątowej Makita GA 9040.

Numer katalogowy oryginału: 516958-8, 517833-1

Indeks: 22-008 -

Wirnik szlifierki GA9049 9047 9057 516708-1

Wirnik do szlifierki kątowej Makita

9047, 9047 F. 9047 SF. 9049, 9049 F, 9049 SF, 1990

Numer katalogowy oryginału: 516708-1

Indeks: 22-009 -

Wirnik szlifierki MAKITA 9059 SF 9057 516713-8

Wirnik do szlifierki kątowej Makita

9059 SF

9057

9059

Numer katalogowy oryginału: 516713-8

Indeks: 22-010 -

Wirnik do szlifierki Makita 9069 9067 9069 S, 516773-0

Wirnik do szlifierki kątowej Makita 9069/9067.

Numer katalogowy oryginału: 516773-0

Indeks: 22-011 -

Wirnik do młotowiertarki HR 2400, 515163-7

Wirnik do młotowiertarki HR 2400.

Numer katalogowy oryginału: 515163-7

Indeks: 22-012 -

Wirnik do młotka Makita HR2410 HR2420, 517403-6

Wirnik do młotowiertarki Makita HR 2410.

Numer katalogowy oryginału: 517403-6

Indeks: 22-013 -

Wirnik wiertarki MAKITA HR2460 HR2470 HR2470F

Wirnik do wiertarki udarowej z elektroniką HR 2470, HR 2470 F, HR 2470 FT, HR 2470 T, HR 2460 F, HR 2460

Numer katalogowy oryginału: 515289-2

Indeks: 22-015 -

Wirnik Makita HR4001C HR4011C HR4010C 513633-7

Wirnik do młota udarowego Makita HR4001C, HR4011C, HR4010C

Numer katalogowy oryginału: 513633-7

Indeks: 22-017 -

Wirnik do młota Makita HR4500C, 516843-5

Wirnik do młoda udarowego Makita HR4500C

Numer katalogowy oryginału: 516843-5

Indeks: 22-018 -

Wirnik do młota kującego Makita HM 1100, 515288-7

Wirnik do młota kującego Makita HM 1100.

Numer katalogowy oryginału: 515288-7

Indeks: 22-020 -

Wirnik do młota MAKITA HM1202, HM1242 C 516803-7

Wirnik do młota udarowo-obrotowego Makita HM1202C .

Numer katalogowy oryginału: 516803-7T

Indeks: 22-021 -

Wirnik przecinarki Makita 2414 2412N, 514543-1

Wirnik przecinarki do metalu Makita 2414.

Numer katalogowy oryginału: 514543-1

Indeks: 22-022 -

Wirnik Makita HP1500, HP1501, HP1510/1600 517108-8

Wirnik Makita HP 1500 / HP 1501 / HP 1510 / 1600, 8450 , 8451

Odpowiednik wirnika o numerze: 517108-8

Indeks: 22-024 -

Wirnik MAKITA HM1304 HM1304B 516864-7

Wirnik do Wirnik HM1304, Młot kłujący Nr oryginalny 516864-7

Indeks: 22-025 -

Wirnik młota Makita HM1203C HM1213C HM1205C, 517818-7

Wirnik do młota kłujacego HM1203C, HM1213C, HM1205C Numer oryginalny 517818-7

Indeks: 22-026 -

Wirnik młota MAKITA HR5201, HR5211 516993-6

Wirnik do młotowiertarki Makita HR5201, HR5211.

Oryginalny numer 516993-6

Indeks: 22-027 -

Wirnik typ MAKITA 9554HN 9554NB 9555HN 9555NB

Wirnik do szlifierki kątowej Makita 9554HN/NB 9555HN/NB.

Numer katalogowy oryginału: 515619-7

Indeks: 22-028 -

Wirnik szlifierka MAKITA GA4540 GA5040 515364-4

Wirnik pasuje do szlifierek MAKITA: GA4540 GA5040

Odpowiednik oryginału o numerze: 515364-4

Indeks: 22-029 -

Wirnik do Makita HR2810 HR2811FT HR2810T HR2810FT, 515294-9

Wirnik do młotowiertarki Makita.

Numer oryginalnej części: 515294-9

Element pasuje do modeli: HR2810, HR2811FT, HR2810T, HR2810FT.

Indeks: 22-030 -

Wirnik MAKITA HR2611FT HR2611F HR2610T HR2600 HR26

Wirnik do młotowiertarki MAKITA HR2600.

Pasuje również do: HR2611FT HR2611F HR2610T HR26

Odpowiednik oryginału o numerze: 515359-7

Indeks: 22-031 -

Wirnik MAKITA GA9050 GA7050R GA9050R 518747-7

Wirnik do szlifierek MAKITA: GA9050 GA7050R GA9050R

Odpowiednik o numerze oryginału: 518747-7

Indeks: 22-032 -

Wirnik MAKITA HP2050 HP2051 DP4011 517414-1

Wirnik do młotowiertarki MAKITA HP2050.

Pasuje również do: HP2051 DP4011

Odpowiednik oryginału o numerze: 517414-1

Indeks: 22-033 -

Wirnik typ MAKITA wiertarki HP 1640, 517458-1

Wirnik do wiertarki udarowej MAKITA HP1640

Pasuje również do: HP1641 HP1640 HP1621 HP1620 HP1641F

Odpowiednik oryginału o numerze: 517458-1

Indeks: 22-034 -

Wirnik do młotka MAKITA HR2300 515354-7

Wirnik do młotowiertarki HR2300.

Odpowiednik oryginału o numerze 515354-7

Indeks: 22-035 -

Wirnik do szlifierki kątowej GE 700 W WP WPS 7-125 115 QUICK 310007680

Wirnik do szlifierki kątowej

W 7-115 Quick, W 7-125 Quick, WP 7-115 Quick, WP 7-125 Quick,

WPS 7-115 Quick, WPS 7-125 Quick ,W 7-115

Numer części oryginalnej: 310007680

Indeks: 23-001 -

Wirnik szlifierka METABO W10-150 WQ10-125 QUICK WE14

Wirnik do szlifierki kątowej Metabo W 10-125, W14

Numery oryginałów: 310007740

PRZED ZAKUPEM PROSZĘ O DEMONTAŻ WIRNIKA I PORÓWNANIE GO WYMIARAMI. ZE WZGLĘDU NA EDYCJE WIRNIKI MIĘDZY SOBĄ MOGĄ SIĘ RÓŻNIĆ.

Nie pasuje do WE 14-125 PLUS z regulacją obrotów

Indeks: 23-003 -

Wirnik METABO WX 23-230 W2231X WX21180 WX21230

Wirnik do szlifierki kątowej WX 23-230 W2231X WX21180 WX212307 W 20-230 21-180 21-230 23-180

PROSZĘ O DEMONTAŻ WIRNIKA ZE SWOJEJ MASZYNY PRZED ZAKUPEM. DO TEGO MODELU MONTOWANE SĄ DWA TYPY WIRNIKÓW. DŁUŻSZY Z TEJ AUKCJI, ORAZ KRÓTSZY, KTÓRY TEŻ JEST WYSTAWIONY.

Indeks: 23-005 -

Wirnik METABO W WX21-230 W23-180 WX23-230 krótki

Wirnik do szlifierki kątowej Metabo W 21-180, WX 21-230, W 23-180. WX 23-230, WX2331X, WX21230, W2080

PROSZĘ O DEMONTAŻ WIRNIKA ZE SWOJEJ MASZYNY PRZED ZAKUPEM. DO TEGO MODELU MONTOWANE SĄ DWA TYPY WIRNIKÓW. KRÓTSZY Z TEJ AUKCJI, ORAZ DŁUŻSZY, KTÓRY TEŻ JEST WYSTAWIONY.

Numer oryginalnej części: 310009880

Indeks: 23-006 -

Wirnik pilarki Black Decker KS805, KS805, BD800, DN800, DN810, KS800, KS810, SR700, 368877-01, 376538-04

Wirnik pilarki do cięcia poprzecznego Black Decker KS 805

Numer katalogowy oryginalnej części: 376538-4, 368877-01

Zastosowanie: KS805, KS805, BD800, DN800, DN810, KS800, KS810, SR700

Indeks: 24-003 -

Wirnik do szlifierki prostej Celma PRAa 40, C-33475P

Wirnik Celma PRAa 40

Numer katalogowy oryginału: C-33475PIndeks: 25-003 -

Wirnik do wiertarki Celma PRCr10 6S, PRCr10 6ES PRCr10 6AEO, C-33723P

Wirnik do wiertarki CELMA

Stosowany w:

- PRCr10 6S, PRCr10 6ES, PRCr10 6 AEO

Odpowiednik oryginału o numerze: C-33723P

Wirnik mechaniczne bez wad oraz jest fabrycznie nowy.

Zdjęcie przedstawia rzeczywisty produkt.

Indeks: 25-005 -

Wirnik wiertarka CELMA PRCb10 PRCb13 aluminiowa

Wirnik do wiertarki Celma PRCb 10 13 PRCb10 PRCu PRAa

Numer oryginalnej części: 1119-190-043T

Indeks: 25-006 -

Wirnik do pilarki Celma DBRCc 67, C-20500/3

Wirnik do pilarki Celma DBRCc 67.

Numer katalogowy oryginału: C-20500/3

Indeks: 25-008 -

Wirnik CELMA PRCj10 LIDER, PRCj10BEO PRCj10CEO C-33871P

Wirnik do wiertarki Celma PRCj 10 LIDER,

PRCj 10BEO

PRCj 10CEO

PRCj 10DEO

PRCj 10FEO

Oryginalny numer C-33871P

Indeks: 25-011 -

Wirnik do szlifierka prosta, Celma PRAa 40c, C-34079

Wirnik do Celma PRAa 40c - szlfierka prosta. Numer oryginalny C-34079

Indeks: 25-013 -

Wirnik HITACHI G10SS G11SR2 G12SR2 G13SS 360802E

Wirnik do szlifierki kątowej Hitachi G10SS, G11SR2, G12SR2, G13SS

Numer oryginału: 360802E

Indeks: 26-001 -

Wirnik szlifierka Hitachi G13SE2 G12SE2 G13SB3, 360603

Wirnik do szlifierki kątowej Hitachi G13SE2.

Zastosowanie: Wirnik Hitachi G13SE2, G12SE2, G13SB3, G12SA3 CM5SB SZCZ

Numer katalogowy oryginalnej części: 360-603, 360-603E, 360-619E, 360-734E,

Indeks: 26-002 -

Wirnik szlifierka HITACHI G18SG G23SE G23SC2 G18SE2 360287E

Wirnik do szlifierek kątowych Hitachi G18SG G23SC2 G18SE2 G23SE G23UB

Numer oryginału: 360-287E

Indeks: 26-003 -

Wirnik Hitachi G23SC3 G23SE2 G18SE3 360594E

Wirnik do szlifierki kątowej Hitachi G23SC3, G23SE2, G18SE3

G23UB2, G23UA2. G23SE2. G23SC3. G23MRU, G23MR. G18UB2. G18UA2. G18SG2. G18SE3. CM7MC

Numer oryginalnej części: 360-594E

Indeks: 26-004 -

Wirnik szlifierka Hitachi G23SF2, G18SH, G23U2 360558

Wirnik do szlifierek kątowych Hitachi

G18SH2, G18U2, G23SF2, G23U2

Numer oryginału: 360-558

Indeks: 26-005 -

Wirnik młotka Hitachi DH24PC3 DH24PB3 DH24PM 360720E

Wirnik do młotowiertarki Hitachi DH24PB3, DH24PC3, DH24PM

Numer oryginału: 360720E

Indeks: 26-006 -

Wirnik młota Hitachi H45MR H45MRY H45SR, 360571E

Wirnik do młota udarowo-obrotowego Hitachi H45MR. Wirnik pasuje również do H45MRY H45SR H 45 MR MRY SR.

Numer oryginału: 360571E

Indeks: 26-008 -

Wirnik młotka Hitachi DH24PB2 DH24PC2 360648E

Wirnik do młotowiertarki Hitachi DH24PB2

Numer oryginalnej części: 360648E

Indeks: 26-010 -

Wirnik Hitachi HiKOKI H65SB H65SB2 H70SA 360286E

Wirnik do Hitachi H65SB2, H65SB H70 i innych. Odpowiednik oryginału 360286E

Indeks: 26-011 -

Wirnik młotka HILTI TE 2, TE 2S, TE 2M, 354768-4

Wirnik do młotowiertarki Hilti TE 2 TE 2M , TE 2S .

Numer oryginału: 354768-4

WIRNIK PIERWSZEJ GENERACJI. PRZED ZAKUPEM PROSZĘ O DEMONTAŻ WIRNIKA I PORÓWNANIE GO Z TYM, KTÓRY ZAPREZENTOWANY JEST W OFERCIE.

Indeks: 27-001 -

Wirnik do młotowiertarki Hilti TE 5, 201536

Wirnik do młotowiertarki Hilti TE 5

Numer oryginalnej części: 201536

Indeks: 27-002 -

Wirnik do młota HILTI TE 14 TE 15 TE 18M, 718878-4

Wirnik do młota udarowo-obrotowego HILTI TE 14 TE 15 TE 18M.

Numer oryginalnej części: 718878-4

Indeks: 27-004 -

Wirnik młot udarowy HILTI TE 54 TE 55 TE 504 203263-9

Wirnik do młota udarowo-obrotowego Hilti TE 54, 55, 504, 505.

Numer oryginału: 203263-9

Indeks: 27-006 -

Wirnik do młota udarowego HILTI TE 72, TE 60, 72343-7

Wirnik do młota udarowo-obrotowego Hilti TE 72.

Numer katalogowy oryginału: 72343-7

Indeks: 27-007 -

Wirnik do młota Hilti TE 74 TE 75 206250-3

Wirnik do młota udarowo-obrotowego Hilti TE 74, TE 75.

Numer oryginału: 206250-3

Indeks: 27-008 -

Wirnik do młota udarowego HILTI TE 76 330432-6

Wirnik do młota udarowo-obrotowego Hilti TE 76.

Numer oryginału: 330432-6

Indeks: 27-009 -

Wirnik do młota Hilti TE 24. TE 25, 301144 277155

Indeks oryginały: 301144 277155

Zastosowanie: TE 24, TE 25

Indeks: 27-012 -

Wirnik do wiertarki Perles SRE 4-613, SRE 4-613S

Wirnik do wiertarki Perles SRE 4-613, SRE 4-613S.

Indeks: 28-003 -

Wirnik do szlifierki kątowej Perles, Celma HSW 315, HSW 325, HSW 325 CE, HSW 325 RE

Wirnik do szlifierki kątowej Perles HSW 315, HSW 325, HSW 325 CE, HSW 325 RE.

Indeks: 28-004 -

Wirnik DeWalt DW 540, 541, BH 40, 41, 577163-04

Wirnik do młota udarowego DW 540(950W), DW 541(1010W).

Numer katalogowy oryginalnej części: 577163-04

Zastosowanie: BH40, BH41, DW540, DW541, BH 40, BH 41, DW 540, DW 541

Indeks: 29-001 -

Wirnik DeWALT DW545 DW543 BH45E 571059-00

Wirnik do młota udarowego DW 545(1100W) oraz BH45E, BH46E, DW543, SH50E, SH50EK, BH 45E, BH 46E, DW 543, DW 545, SH 50E, SH 50EK.

Numer katalogowy oryginalnej części: 571059-00

Indeks: 29-002 -

Wirnik do DeWALT DW563, DW566, D25002K, D25003K 585289-00

Wirnik do Młotowiertarki DW 566 oraz DW563, D25002K, D25003K, BH22, BH24

Numer katalogowy oryginalnej części: 585289-00

Indeks: 29-003 -

Wirnik DeWALT D28135 D28137 D28136 D28132C

Wirnik do szlifierki kątowej DeWalt D28132C, D28135, D28136, D28137.

Numer Oryginalny N398000 / 623584-07 .

Indeks: 29-005 -

Wirnik DeWALT DW501 DW505 DW241 387614-01

Wirnik do wiertarki udarowej DeWalt DW241 DW 501 DW 505 DW501 DW505 BM19

Numer oryginalnej części: 387614-01, 387614-00

Indeks: 29-006 -

Wirnik typ DeWalt D25500, D25600, D25830 580383-02

Wirnik do DeWalt D25500 typ 1,2, D25600 typ 1,2, D25830 typ 1,2

D25500 typ 1,2,

D25600 typ 1,2,

D25830 typ 1,2

Odpowiednik numerów oryginalnych:

N079385 / 580383-02

Indeks: 29-007 -

Wirnik do szlifierki DeWalt D28414, 28400, 28401, 28410, 28413, 28415, 583530-06 / N029094

Wirnik do DeWalt D28400, D28401, D28410, D28411, D28413, D28414, D28415

Numer oryginalnej części: 583530-06, N029094

Indeks w sklepe langner-czesci.pl: 29-008

Typ: Zamiennik

Indeks: 29-008 -

Wirnik DeWALT DWE4050 DWE4051DWE4056 N181765

Wirnik do szlifierki kątowej DWE4050 DWE4051

Numer oryginalnej części: N181765

Indeks: 29-009 -

Wirnik DeWalt DWE4237 DWE4235 DWE4233 N442428

Wirnik do szlifierki kątowej marki DeWalt.

Pasuje do modeli: DWE4237 DWE4235 DWE4233

Odpowiednik oryginału o numerze: N442428

Wykaz modeli:

DWE4237-Type-3

DWE4237-Type-1

DWE4235-Type-3

DWE4233-Type-3

DWE4233-Type-1

Indeks: 29-012 -

Wirnik do szlifierki kątowej BUŁGAR Eltos-Elprom M-851

Wirnik do szlifierki kątowej Eltos-Elprom M-851.

Indeks: 30-002 -

Wirnik do szlifierki kątowej BUŁGAR Eltos-Elprom M-852

Wirnik do szlifierki kątowej Eltos-Elprom M-852.

Indeks: 30-003 -

Wirnik do szlifierki kątowej Eltos-Elprom BUŁGAR MA 2000, MBA 2001

Wirnik do szlifierki kątowej Eltos-Elprom MA 2000, MBA 2001.

Indeks: 30-005 -

Wirnik do szlifierki kątowej BUŁGAR Eltos-Elprom MA 2001

Wirnik do szlifierki kątowej Eltos-Elprom MA 2001

Indeks: 30-006 -

-

-

-

Wirnik do młotowiertarki SDS + - 6 zębów - chińskie marketowe młotowiertarki

Wirnik do młotowiertarki SDS + - 6 zębów - chińskie marketowe młotowiertarki

Indeks: 70-002 -

Wiatrak wentylato do GSH388 bez magnesu

Wentylator do GSH388 bez magnesu

Średnica Zewnętrzna: 79mm

Średnica Wewnętrzna: 15-16.5 (stożek)

Grubość: 17mm

Indeks: R-079 -

-

Komplet GBH 7 DE - szczotki, łożyska, mimośród

Komplet GBH 7 DE - szczotki, łożyska, mimośród

Indeks w sklpeie: 21-037SLK

Na komplet składa się: 21-037(wirnik), 46-010(szczotki), NKE628-2RS, 69-072(koło mimośrodowe), 13-014(łożysko igiełkowe)

Numery katalogowe oryginalnych części: 1614010213(wirnik), 1617014135(szczotki), NKE628-2RS(1610900026), 1616317067(koło mimośrodowe), 1610910089(łożysko igiełkowe)

Typ: Zamiennik

Stan: Nowy

Indeks: 21-037SLK -

Wirnik BOSCH GBH2-24DSR GBH2SR GBH2-24DFR 5 ZĘBÓW

Wirnik do GBH2-24DSR z 5-cioma zębami wraz ze szczotkami.

Wirnik pasuje jeszcze do amatorskich młotowiertarek GRAPHITE czy EUROTEC.

PRZED ZAKUPEM PROSIMY O DEMONTAŻ WIRNIKA I PORÓWNANIE GO Z OFERTĄ.

Indeks: 21-030S -

Wirnik do BOSCH GSH11E GBH11E + szczotki

Wirnik do młota BOSCH GSH GBH 11E wraz ze szczotkami.

Indeks: 21-039S -

WIRNIK wiertarka CELMA PRCr 10/6 AEO ES BEO 500W

Wirnik oraz szczotki węglowe do wiertarki CELMA

Stosowany w:

- PRCr10 6S, PRCr10 6ES, PRCr10 6 AEO

Odpowiednik oryginału o numerze: C-33723P

Odpowiednik oryginału o numerze szczotki: 1119-110-080

Wirnik mechaniczne bez wad oraz jest fabrycznie nowy.

Zdjęcie przedstawia rzeczywisty produkt.

Indeks: 25-005S -

Wirnik SZLIFIERKI GA9050 GA9050R + szczotki

Wirnik do dużej szlifierki MAKITA GA9050 wraz z wysokiej jakości szczotkami węglowymi.

Indeks: 22-032S -

Wirnik szlifierki BOSCH GWS11CI CIE HILTI

Wirnik do szlifierki GWS11CI wraz ze szczotkami.

Indeks: 21-017S -

Wirnik do BOSCH GWS 7-115 7-125 GEF 7E 1619P05210

Wirnik do szlifierki BOSCH GWS7 z długim pakietem wraz ze szczotkami wysokiej jakości.

Indeks: 21-043S -

Wirnik do HITACHI G13SE2 G13SB3 + szczotki

Wirnik wraz z wysokiej jakości szczotkami węglowymi do szlifierek HITATCHI / HI-KOKIE

Indeks: 26-002S -

Wirnik do HITACHI G13SE2 G13SB3 PRZEKŁADNIA

Wirnik wraz z wysokiej jakości przekładnią kątową do szlifierek HITATCHI / HI-KOKI

Indeks: 26-002K -

Wirnik BOSCH GWS 10-125 C CE PWS 10-125 GWS1000

Wirnik do szlifierek GWS1000 GWS10 BOSCH wraz ze szczotkami węglowymi.

Indeks: 21-016S -

Wirnik Bosch GWS 6-115 6-115E GWS6-115 GWS6-115E

Wirnik do szlifierek kątowych BOSCH GWS6 wraz ze szczotkami wysokiej jakości.

Indeks: 21-010S -

Wirnik MAKITA 9565CV 9565CR 9565C 9564CV koło

Wirnik do szlifierek MAKITA z przekładnią kątową.

Indeks: 22-005K -

Wirnik do podkaszarki kosy wieloklin flora geko black

Wirnik do podkaszarki kosy wieloklin flora geko black

Indeks: 70-006 -

Wirnik do szlifierki kątowej Flora 230, max G1802-2 i wielu innych

Wirnik do szlifierki kątowej Flora 230, max G1802-2 i wielu innych

Indeks: 70-016 -

Wirnik do szlifierki mimośrodowej dł.150mm

Wirnik do szlifierki mimośrodowej dł.150mm

Indeks: 70-026 -

Pordzewiały wirnik do szlifierki Makita 9015 9016 B 516334-6

Pordzewiały wirnik do szlifierki Makita 9015 9016 B 516334-6

Indeks: 22-036R -

Pordzewiały wirnik do polerki geko black einhell 6 zębów

Pordzewiały wirnik do polerki geko black einhell 6 zębów

Indeks: 70-021R -

Pordzewiały wirnik do kosy dł. 140mm pak. 38X35mm podkaszarki

Pordzewiały wirnik do kosy dł. 140mm pak. 38X35mm podkaszarki na wieloklin + łożyska 607ZZ i 608ZZ

Indeks: 70-022R -

-

Wirnik do wyrzynarki MAKITA 4322 4323 4324 4329 4327 515719-3

Wirnik do wyrzynarki MARKI

Stosowany w:

- 4322 4323 4324 4329 4327

Odpowiednik oryginału o numerze:

- 515719-3

Zdjęcie przedstawia rzeczywisty produkt.

Indeks: 22-037 -

Wirnik szczotki łożyska do wiertarki CELMA PRCr 10/6 AEO ES BEO 500W

Zestaw serwisowy do wiertarki CELMA.

Pasuje do:

- PRCr10 6S, PRCr10 6ES, PRCr10 6 AEO

Na sprzedawany komplet składa się:

- Wirnik

- Łożysko 625 RS 2RS wysokoobrotowe PREMIUM

- Łożysko 627 RS 2RS wysokoobrotowe PREMIUM

- Szczotki węglowe komplet; dwie sztuki

Odpowiednik oryginału o numerze:

- Wirnik: C-33723P

- Szczotki: 1119-110-080

Zdjęcie przedstawia rzeczywisty komplet.

Indeks: 25-005SL-2 -

Wirnik szlifierka MAKITA do szlifierki GA5030 GA4530R GA5030R komplet

Wirnik do szlifierki kątowej MAKITA w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- GA5030, GA4530R, GA5030R, GA4530, PJ7000

Odpowiednik oryginału o numerze:

- Wirnik: 517649-4

- Szczotki węglowe: 194722-3, CB459

Indeks: 22-004SLA-2 -

WIRNIK do szlifierki MAKITA 9565CV 9565CVR 9565CR 9565C 9565CV

Wirnik do szlifierki kątowej MAKITA w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- 9565CV 9565CR 9565C

W zestawie:

- Wirnik

- Łożysko 6001 RS 2RS C3 wysokoobrotowe PREMIUM

- Łożysko 627 RS 2RS C3 wysokoobrotowe PREMIUM

- Szczotki węglowe z bezpiecznikami komplet; 2 sztuki

Odpowiednik oryginału o numerze:

- Wirnik: 515228-2

- Szczotki węglowe: 194722-3, CB459

Indeks: 22-005SL-2 -

Wirnik do szlifierki BOSCH GWS 7-115 GWS 7-125 1619P05210 szczotki

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- GWS 7-115 GWS 7-125

W zestawie:

- Wirnik

- Łożysko 607 RS 2RS C3 wysokoobrotowe PREMIUM

- Łożysko 608 RS 2RS C3 wysokoobrotowe PREMIUM

- AMORTYZATOR

- Szczotki węglowe z bezpiecznikami komplet; 2 sztuki

Odpowiednik oryginału o numerze:

- Wirnik: 1619P05210

- Szczotki węglowe: 1619P02870

Indeks: 21-043SL-2 -

Wirnik szlifierki DO BOSCH GWS850CE GWS850C 1 604 010 667 szczotki

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- GWS 850C, GWS 850CE, GWS 780C, GWS 8-100C, GWS 8-125C, GWS 780C, GWS 8-100CE, GWS 8-125CE

Odpowiednik oryginału o numerze:

- Wirnik: 1 604 010 667

- Szczotki węglowe: 2 604 321 005

Indeks: 21-012SLA-2 -

Wirnik szlifierka BOSCH GWS 14-125 CI CIE 1400 1 604 010 A90 zestaw

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- GWS1400, GWS1400C, GWS14-125CI, GWS14-125CIE, GWS 1400, GWS 1400C, GWS 14-125CI, GWS 14-125CIE

Odpowiednik oryginału o numerze:

- Wirnik: 1 604 010 A90, 1 604 010 A22, 1 604 010 A86

- Szczotki węglowe: 1 607 014 138 bądź 1 607 014 176, 1 607 014 172

Indeks: 21-020SL-2 -

Wirnik szlifierka BOSCH GWS 14-125 CI CIE 1400 1 604 010 A90 magnes zestaw

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami, magnesem oraz szczotkami.

Wirnik montowany w:

- GWS1400, GWS1400C, GWS14-125CI, GWS14-125CIE, GWS 1400, GWS 1400C, GWS 14-125CI, GWS 14-125CIE

Odpowiednik oryginału o numerze:

- Wirnik: 1 604 010 A90, 1 604 010 A22, 1 604 010 A86

- Szczotki węglowe: 1 607 014 138 bądź 1 607 014 176, 1 607 014 172

- MAGNES ORYGINALNY: 1 607 000 378

Indeks: 21-020SLUM -

Wirnik szlifierka BOSCH GWS 10-125 C CE PWS 10-125 GWS1000 szczotki

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami, magnesem oraz szczotkami.

Wirnik montowany w:

- GWS 10-125 Z, GWS 9-125 (0601801008) GWS 1000, GWS 10-125 /BEZ OZNACZENIA C LUB CE

Odpowiednik oryginału o numerze:

- Wirnik: 1 604 010 A20

- Szczotki węglowe: 1 607 014 138 bądź 1 607 014 176, 1 607 014 172

Indeks: 21-016SLU-2 -

WIRNIK DO SZLIFIERKI BOSCH GWS 9-115 GWS 9-125 S 1619P10952 ZESTAW

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- GWS 9-115, GWS 9-125, GWS 9-115 S, GWS 9-125 S, GWS 9-125 P

Odpowiednik oryginału o numerze:

- Wirnik: 1619P10952

- Szczotki węglowe: 1619P11715, 1 619 P11 715, 2 604 321 005, 2604321005, A96

Indeks: 21-063SL-2 -

Wirnik szczotki do szlifierki BOSCH GWS17-125 CI CIE GWS 15-125 1607000V35

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- GWS 15-125 CI , GWS 15-125 CIE ,GWS 15-125 CIP , GWS 15-125 CIPX , GWS 15-125 CIEX , GWS 15-125 CIEP , GWS 17-125 CIE , GWS 17-125 CI , GWS 17-125 CIX , GWS 17- 125 CIEX

Odpowiednik oryginału o numerze:

- Wirnik: 1607000V35, 1 607 000 V35

- Szczotki węglowe: 1 607 000 V37 lub 1 607 000 V53

Indeks: 21-049ALS-2 -

Wirnik szlifierki DO BOSCH GWS 15-125 CIT GWS 17-125 CIT INOX 1607000V36

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- GWS 15-125 CIT, GWS 15-150 CI, GWS 15-150 CIP, GWS 17-125 CIT, GWS 17-150 CI, GWS 17-125 INOX, GWS 15-125 INOX

Odpowiednik oryginału o numerze:

- Wirnik: 1607000V36, 1 607 000 V36

- Szczotki węglowe: 1 607 000 V37 lub 1 607 000 V53

Indeks: 21-052ALS-2 -

Wirnik szlifierki MAKITA GA9020 GA9020R GA9020S ŁOŻYSKA SZCZOTKI

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- GA 9020, MT 900, MT 901, GA7020, GA7020R. GA7020SF

Odpowiednik oryginału o numerze:

- Wirnik: 517793-7

- Szczotki węglowe: CB203, CB204, 191957-7 / 191953-5

Indeks: 22-006SL -

Wirnik do wiertarki GBH 2-26 DRE DFR 226 ŁOŻYSKA SZCZOTKI ZESTAW

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- GBH 2-26, GBH 2-26 DRE, GBH 2-26 DE, GBH 2-26 DFR, GBH 2400, GBH 2600

Odpowiednik oryginału o numerze:

- Wirnik: 1614010709 / 1617000560, 1 614 010 709 / 1 617 000 560

- Szczotki węglowe: 1 617 000 525

Indeks: 21-032SL -

Wirnik szczotki do BOSCH GWS17-125 CI CIE GWS 15-125 MAGNES KPL

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami, magnesem oraz szczotkami.

Wirnik montowany w:

- GWS 15-125, GWS 17-125

Odpowiednik oryginału o numerze:

- Wirnik: 1607000V35, 1 607 000 V35

- Szczotki węglowe: 1 607 000 V37 lub 1 607 000 V53

- ORYGINALNY MAGNES : 1 607 000 v38, 1607000V38

Indeks: 21-049ALM-2 -

WIRNIK szlifierka MAKITA GA9050R GA9050 GA7050R szczotki łożyska

Wirnik do szlifierki kątowej MAKITA w komplecie z łożyskami oraz szczotkami.

Wirnik montowany w:

- GA9050 GA7050R GA9050R

Odpowiednik oryginału o numerze:

- Wirnik: 518747-7

- Szczotki węglowe: 191957-7 / 191953-5, CB203 CB204

Indeks: 22-032SL-1 -

Wirnik GBH2-24DSR GBH2SR GBH2-24DFR SZCZOTKI ŁOŻYSKA

Wirnik do szlifierki kątowej BOSCH w komplecie z łożyskami, amortyzatorem oraz szczotkami.

Wirnik montowany w:

- GBH2-24DSR GBH2SR GBH2-24DFR 6 ZĘBÓW

Odpowiednik oryginału o numerze:

- Wirnik: 1614010227, 1 614 010 227

- Szczotki węglowe: 1617014134 lub 1617014127, A96, 1 617 014 134 lub 1 617 014 127, A 96

Indeks: 21-031SLL -

Wirnik do młotka BOSCH GBH 5-40 DCE 5-40 DE 1614011098 GSH 5E GSH 5CE

Wirnik do młota BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik stosowany w modelach:

- GBH5-40DE, GBH5-40DCE, GSH5E, GSH5CE, GBH 5-40DE, GBH 5-40DCE, GSH 5E, GSH 5CE

Odpowiednik oryginału o numerze:

- Wirnik: 1614011098

- Szczotki węglowe: 1617014135

Indeks: 21-035SL-2 -

Wirnik do szlifierki Bosch GWS PWS 20-180 20-230 21-180

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

- GWS 19-180, GWS 2000-180J, GWS 19-230,GWS 2000-230, GWS 2000-230 J, GWS 21 U, GWS 21-180, GWS 20-230, GWS 21-230, PWS 1700, PWS 20-230, PWS 18-230 J.

Odpowiednik oryginału o numerze:

- Wirnik: 1604011145/1604011148

- Szczotki węglowe: 1607014130 lub 1607014171

Indeks: 21-021SL-2 -

Wirnik do szlifierki Bosch GWS PWS 20-180 20-230 21-180 1700 duże szlifierki

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

- GWS18U, GWS 21U, GWS 18-180, GWS 19-180, GWS 19-230, GWS 20-180, GWS 20-230, GWS 21-180, GWS 21-230, GWS2000-230, PWS18-230, PWS 19-230, PWS 20-230J, PWS 18-230J, GWS 18-180, GWS 19-180

Odpowiednik oryginału o numerze:

- Wirnik: 1604011148

- Szczotki węglowe: 1607014130 lub 1607014171

Indeks: 21-022SL-2 -

Wirnik do młota BOSCH GSH11E GSH 11 E GBH11DE 1614011072

Wirnik do młotka BOSCH w komplecie z łożyskami oraz szczotkami.

W zestawie:

- Wirnik

- Łożysko igiełkowe

- Łożysko 6200 ZZ 2ZZ C3 wysokoobrotowe PREMIUM

- Szczotki węglowe z bezpiecznikami komplet; 2 sztuki

Odpowiednik oryginału o numerze:

- Wirnik: 1614011072

- Szczotki węglowe:1617014126

- Łożysko igiełkowe: 1610910089

➡️Wirnik pasuje do:

- GSH 11 E, GBH 11 DE

Indeks: 21-039SL-2 -

Wirnik do młota BOSCH GSH11E GSH 11 E 1614011072 SZCZOTKI ŁOŻYSKA

Wirnik do młotka BOSCH w komplecie z łożyskami oraz szczotkami.

W zestawie:

- Wirnik

- Łożysko igiełkowe

- Łożysko 6200 ZZ 2ZZ C3 wysokoobrotowe PREMIUM

- Koło mimośrodowe

- Szczotki węglowe z bezpiecznikami komplet; 2 sztuki

➡️Wirnik pasuje do:

- GSH 11 E

Indeks: 21-039SLK -

Wirnik do Makita HR4001C HR4011C HR4010C 513633-7 ZESTAW

Wirnik do młotka MAKITA w komplecie z łożyskami oraz szczotkami.

W zestawie:

- Wirnik

- Łożysko 608 RS 2RS C3 wysokoobrotowe PREMIUM

- Łożysko 6201 RS 2RS C3 wysokoobrotowe PREMIUM

- Szczotki węglowe z bezpiecznikami komplet; 2 sztuki

Odpowiednik oryginału o numerze:

- Wirnik: 513633-7

- Szczotki węglowe: CB-350, 194160-9

➡️Wirnik pasuje do:

- HR 4001 C, HR 4010 C, HR 4011 C

Indeks: 22-017SL -

Wirnik do DeWalt D28135 D28136 D28137 D28132C zestaw

Wirnik do szlifierki DeWALT w komplecie z łożyskami oraz szczotkami.

W zestawie:

- Wirnik

- Łożysko 607 RS 2RS C3 wysokoobrotowe PREMIUM

- Łożysko 608 RS 2RS C3 wysokoobrotowe PREMIUM

- Szczotki węglowe z bezpiecznikami komplet; 2 sztuki

Odpowiednik oryginału o numerze:

- Wirnik: N398000 / 623584-07

- Szczotki węglowe: 1003860-00 lub 636128-03

Indeks: 29-005SL-2 -

WIRNIK DO BOSCH GWS 11-125 CI CIE CIH 1 604 010 A21 zestaw

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik stosowany w modelach:

- GWS 11-125 CI, GWS 11-125 CIE, GWS 11-125 CIH. HILTI DAG125SE, DAG 125S

Odpowiednik oryginału o numerze:

- Wirnik: 1604010A21

- Szczotki węglowe: 1607014138, 1607014176, 1607014172, A77

Indeks: 21-017SL-2 -

WIRNIK DO BOSCH GWS 11-125 CI CIE CIH 1 604 010 A21 zestaw

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

Wirnik stosowany w modelach:

- GWS 11-125 CI, GWS 11-125 CIE, GWS 11-125 CIH. HILTI DAG125SE, DAG 125S

Odpowiednik oryginału o numerze:

- Wirnik: 1604010A21

- Szczotki węglowe: 1607014138, 1607014176, 1607014172

- Magnes oryginalny: 1607000378

Indeks: 21-017SLM -

Wirnik szlifierka BOSCH PWS 550 600 700 6 7 115 2609000761

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

- PWS 550, PWS 600, PWS 650, PWS 700, PWS 6-115, PWS 7-115, PWS 720-115

Odpowiednik oryginału o numerze:

- Wirnik: 2609000761

- Szczotki węglowe: 1607014116

Indeks: 21-024SL-2 -

WIRNIK do wiertarki HITACHI HIKOKI DH24PC3 DH24PB3 ZESTAW

Wirnik do wiertarki HITACHI HIKOKI w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

-

DH24PB3, DH24PC3, DH26PB

Odpowiednik oryginału o numerze:

- Wirnik: 360720E

- Szczotki węglowe: 999-041

Indeks: 26-006SL -

-

Wirnik do MAKITA GA9040R GA9040 GA7040 szczotki łożyska

Wirnik do szlifierki MAKITA w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

- GA7040S, GA7040SF, GA7040R, GA9040R, GA9040S

Odpowiednik oryginału o numerze:

- Wirnik: 516958-8, 517833-1

- Szczotki węglowe: CB203, CB204, 191957-7, 191953-5

Indeks: 22-008SL -

Wirnik do wiertarki MAKITA HP1620 H1621 HP1640 szczotki łożyska

Wirnik do wiertarki MAKITA w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

- HP1641 HP1640 HP1621 HP1620 HP1641F

Odpowiednik oryginału o numerze:

- Wirnik: 517458-1

- Szczotki węglowe: 191962-4, CB419, CB-419

Indeks: 22-034SL -

Wirnik do wiertarki BOSCH GBH 2-28F 2-28 DV 2-28 DFV komplet

Wirnik do młotowiertarki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

-

GBH 2-28 DV, GBH 2-28 DFV, GBH 2-28 F, GBH 2-28, GBH 2-28 D, BHD-2-28 EC, BH 2-28 MES, H 28 MLE POWER, H 28 MLS POWER

Odpowiednik oryginału o numerze:

- Wirnik: 1614010262

- Szczotki węglowe: 1617000525

Indeks: 21-046SL -

-

Wirnik BOSCH GBH 7 DE 7-45 DE 7-46 DE 1614010213 ZESTAW

Wirnik do MŁOTKA BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

- GBH7DE, GBH7-45DE, GBH7-46DE, GBH 7DE, GBH 7-45DE, GBH 7-46DE

Odpowiednik oryginału o numerze:

- Wirnik: 1614010204, 1614010205, 1614010213

- Szczotki węglowe: 1617014135 zamienne z 1617014144, A69

Indeks: 21-037SL -

Wirnik do szlifierki BOSCH GWS 10-125 C CE GWS 1000 PWS 10 HILTI AG ZESTAW

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

- GWS 10 C. GEB 1000 CE, OSB 1020 CE, nowy typ: GWS 10-125 CE, PWS 10-125 CE, HILTI AG 125 S, GWS 1000

Odpowiednik oryginału o numerze:

- Wirnik: 1604010640

- Szczotki węglowe: 1607014138, 1607014176, 1607014172, A77

Indeks: 21-015SL -

Wirnik do szlifierki BOSCH GWS 14-125 C CE PWS 13-125 CE zestaw

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

- GWS 14-125 C, GWS 14-125 CE, PWS 13-125 CE(bez regulacji obrotów)

Odpowiednik oryginału o numerze:

- Wirnik: 1604010650

- Szczotki węglowe: 1607014138, 1607014176, 1607014172, A77

Indeks: 21-018SL -

Wirnik DO szlifierki BOSCH GWS 23-230 GWS 24-230 szczotki łożyska

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

- GWS 23-230. GWS 23-180, GWS 23-230, GWS 24-180, GWS 24-230, GWS 24-300J, GNF 65 A.

Odpowiednik oryginału o numerze:

- Wirnik: 1604011153

- Szczotki węglowe: 1607014130, 1607014171, 1619P10476

Indeks: 21-023SL -

Wirnik szlifierki DO BOSCH GWS12-125 CI CIE GWS13-125 CI CIE zestaw

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

-

GWS 12-125, GWS 12-125 CIE, GWS 12-125 CIEP

Odpowiednik oryginału o numerze:

- Wirnik: 1607000V33

- Szczotki węglowe: 1607000V37, 1607000V53, 1604321187, HILTI 341529

Indeks: 21-048SL -

-

Wirnik szlifierki DO BOSCH GWS12-125 CI CIE GWS13-125 CI CIE magnes

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

-

GWS 12-125, GWS 12-125 CIE, GWS 12-125 CIEP

Odpowiednik oryginału o numerze:

- Wirnik: 1607000V33

- Szczotki węglowe: 1607000V37, 1607000V53, 1604321187, HILTI 341529

Magnes, łożyska oryginalne: 1607000V38

Indeks: 21-048SLM -

-

Wirnik do szlifierki BOSCH GWS 19-125 CI CIE HILTI AG125-19SE 1600A00D2N

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

-

GWX 19-125, GWS 19-125 CI 3 601 G9N 000, GWS 19-125 CIE

Odpowiednik oryginału o numerze:

- Wirnik: 1600A00D2N

- Szczotki węglowe: 1607000V37, 1607000V53, 1604321187, HILTI 341529

Indeks: 21-064SL -

-

Wirnik do szlifierki BOSCH GWS 19-125 CI CIE HILTI AG125-19SE ZESTAW

Wirnik do szlifierki BOSCH w komplecie z łożyskami oraz szczotkami.

➡️Wirnik stosowany w modelach:

-

GWX 19-125, GWS 19-125 CI 3 601 G9N 000, GWS 19-125 CIE

Odpowiednik oryginału o numerze:

- Wirnik: 1600A00D2N

- Szczotki węglowe: 1607000V37, 1607000V53, 1604321187, HILTI 341529

Magnes, łożyska oryginalne: 1607000V38

Indeks: 21-064SLM -

-

What is a rotor?

The rotor for power tools, is a key component inside many electrical devices such as:

- drills

- angle grinders

- demolition hammers

- hammer

- drills

- screwdrivers

It is the rotating component of an alternating current (AC) or direct current (DC) electric motor. It is responsible for converting electrical energy into mechanical energy.

How is the rotor constructed?

- Magnetic core: It consists of a set of laminated steel sheets that form a cylinder.

- The lamination reduces energy losses due to eddy currents.

- Winding

- :

- A copper winding is wound on the core.

- The current flowing through this winding creates a magnetic field.

- Commutator (in DC motors): Located at one end of the rotor and consists of segments that conduct current to the rotor winding. It works with brushes that supply current to the commutator.

How does the rotor function?

- Magnetic induction: The electric current flowing through the rotor winding creates a magnetic field that interacts with the magnetic field of the stator (the stationary part of the motor).

- Rotational motion: The interaction of the magnetic fields of the rotor and stator causes the rotor to start rotating, converting electrical energy into mechanical energy

- .

Types of motors:

- Direct current (DC) motors:

- The rotors in these motors have commutators and brushes.

- Alternating current (AC) motors: Can be of various types, such as induction or synchronous, and in most cases do not have commutators or brushes.

Maintenance and repair:

- Rotors can wear out due to heavy use, overheating or mechanical damage.

- Typical symptoms of rotor damage include sparking, abnormal sounds or a drop in tool power.

- Repairs may include winding replacement, commutator or bearing replacement. Or even the stator. To extend the life of the rotor, it is recommended to buy good quality carbon brushes.